TECHNICAL INFORMATION

Amoz Securiglass security glasses are laminated glasses designed to meet specific perceived threats, either physical or ballistic, which may be directed against the glazing Laminated glass Is produced by bonding two or more sheets of glass under heat and pressure with polyvinylbutyral interlayers The interlayers ensure that the Integrity of the glass is maintained even when attacked The performance of the laminated glasses Is determined by the thickness of interlayer and glass incorporated into the specification.

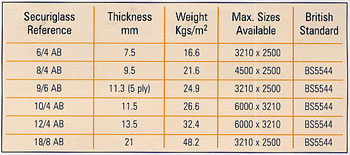

PHYSICAL ATTACK RESISTANT GLASSES

- are currently covered by British Standard BS 5544 (European legislation pending),

- may be constructed with one or two sheets of glass but contain a minimum of 152mm of interlayer,

- can be glazed into timber or metal framing systems, although attention must be given to rebate depths to ensure sufficient grip under attack,

- can Incorporate special glasses including solar control, patterned and non- reflective glasses,

- can be incorporated into double glazed units for heat and acoustic control reasons,

- can be adapted for blast resistant applications

AREAS OF APPLICATION

- Security screens for staff when protection Is only required at a physical attack level

- Secure areas In Industrial and commercial buildings

- Glazed areas where there is a risk of explosion

- Museums and art galleries

- Domestic security glazing

- Prisons and detention centres

BALLISTIC ATTACK RESISTANT GLASSES

- are currently covered by British Standard B5 5051 (European legislation pendings);

- are constructed with four or more sheets of glass: increasing the amount of glass increases the ballistic resistance. Increasing the amount of interlayer improves the glass's physical attack resistance;

- can be glazed into timber or metal framing systems, although attention must be given to rebate depths to ensure sufficient grip under attack;

- can incorporate special glasses including solar control, patterned and non-reflective glasses;

- can be incorporated into double glazed units for heat and acoustic control reasons;

- can be adapted for blast resistant applications.

AREAS OF APPLICATION

- Bank / Building Society / Post Office security screens

- External glazing in high risk areas

- Embassies

- Rent and Rate Offices

- Betting shops

- Armoured and V.I.P vehicles

- High risk residences

- Government buildings

- Police Stations

- Commercial and industrial applications

- Gate Houses.

Special glasses can be developed to suit specify requirements where a suitable item does not exist in the standard urge.

* Test paper: 3 strikes from 3 metres: equilateral triangle at 100mm centres.

** Test patter: 1 strike from 10 metres: centre of panel.

*** Test patted: 3 strikes from 10 metres: equilateral triangle at 100mm centres.

N.B. The inclusion of the prefix ''HP'' denotes that the construction of the glass incorporates a 1 to 1 .5mm thick leaf of glass to the non-attack side of the laminate to reduce the amount of spelling when attacked. Glasses are available without this layer should stalling not be considered a hazard. Details are available on request from Securiglass Company Ltd.

GLAZING RECOMMENDATIONS

Both Physical and Ballistic Attack Resistant glasses from Securiglass can be glazed externally or internally. In both cases, external glazing systems should ensure that any water will drain away quickly.

Physical Attack Resistant Glass

- The rebates should allow a minimum edge cover of 12mm.

- The glass can be glazed into hardwood or metal frames.

- Setting or spacer blocks should be used to avoid glass rim contact.

- Non-oil based glazing compounds should be used.

(For information on Blast Resistant glazing, please contact the Securiglass Technical Department).

Ballistic Attack Resistant Glass

- Minimum edge cover of 20mm.

- The glass should not come into contact with the framework.

- Any bedding compounds should be compatible with the PVB interlayer.

- Frames should be made of steel or reinforced aluminum.

- Setting blocks should be placed 25 per cent of the base in from either end.

- Care should be taken to ensure that the shall limiting layer is glazed away from the predicted attack side.

Note: Because of the weight of the glass and framework 'attention must be paid to the original structure and its ability to support its weight.

Optional compositions

Physical and Ballistic Attack Resistant Glasses are available in a range of non-standard compositions, including:

- incorporating body tinted solar control glasses

- incorporating tinted PVB interlayers

- incorporating reflective solar controlled glasses

- incorporating a wide range of patterned glasses

- can be combined into double glazed units

Whilst every effort has been made to ensure that the contents of this Technical Data Sheet are accurate, Securiglass cannot accept responsiblity for omissions or errors. Securiglass Physical Attack Resistant Glass and Ballistic Attack Resistant Glass undergo a continuous test programme; details of test evidence are available on request. |