| |

SALES : +6012 3327428

|

|

|

PROTECTION AGAINST

NUCLEAR WEAPONS

CHEMICAL WEAPONS

CONVENTIONAL WEAPONS

COMBINED WAR EFFECTS |

Purpose and requirements

The ventilation and heating installations of the shelter facilities serve the following purpose:

- supply of air for breathing

- removal of exhaust air

- heating

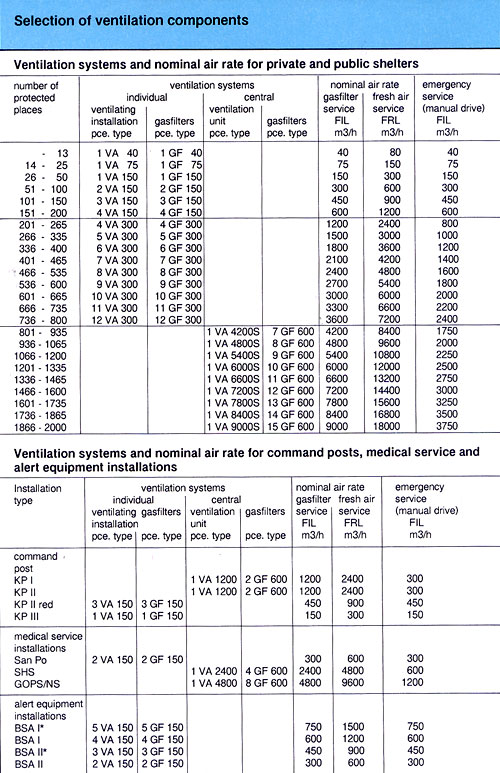

These facilities must be protected against the main effects of weapons (shock wave, vibrations, EMP). Moreover, it has to been seen to the fact that no chemical agents or radioactive fallouts can penetrate into the shelter filter, overpressure).The requirements ("Selection of ventilation components") which have to be fulfiller by the ventilation installations of all types of shelter facilities are determined in table 1.01.057 ''Selection of ventilation components". The nominal air quantities mentioned in this table are sufficient to provide acceptable climatic conditions for all types of operation of the facilities. These calculations take into account that:

- the CO2-concentration remains low and enough oxygen is supplied

- temperature and humidity stays within acceptable limits

- there is no unacceptable disturbance by odours

- there is enough air for air circulation in the air locks during filter operation

For reasons of simplicity and uniformity it is advisable to use standardized ventilation components. The requirements of these components have to fulfill the special performance specifications of BZS (Swiss Civil Defence). The data given in table 1.99.50 ''Selection of ventilation components'' serve for an easy selection of the necessary air quantities and the appropriate components. The ventilation installation with all flow resistances has to be calculated in every detail. |

Operation types

The action phase of Civil Defence and thus, the use of the shelter requires different levels of ventilation and leads us to the following operation types:

- maintenance operation (during peace time)

- fresh air operation [without gasfilter] (during the pre-attack and recovery period)

- gasfilter operation (during the attack and post attack period in case of the threat or actual use of chemical agents)

- ventilation-interuption (during the attack period as a protective measure against burning fumes and relief of the gasfilter)

- emergency operation (in case of failure of the electric supply system)

- Maintenance operation

To protect the shelter equipment against humidity damage, the air relative humidity in the shelter is kept below 65 % by means of mobile dehumidifiers. To achieve an even atmospheric humidity in all rooms, the air is periodically recirculated within the installation.

For this purpose a timer switches on the ventilation unit working on return air after certain time intervals. In case of favourable outside conditions, the. shelter is ventilated with fresh air (dehumidifier switched off) When the use of the shelter is planned (e.g. preparation for moving in), the room temperature can be raised by approx. 10C by means of the normal heating system.

- Fresh air operation (without gasfilter)

During all action phases when the outside air is not contaminated, the shelter is ventilated with fresh air. The fresh air passes only the pre-filters, which keep off dust (e.g. from building debris or from radioactive fallouts). Rooms with a higher occupancy are supplied with larger air rates than less occupied rooms. Rooms with odour development, such as kitchen and toilets, must be equipped with an exhaust air ventilation system.

- Gasfilter operation

In case of threat of use of chemical agents, the outside air coming through the explosion protection valves and pre-filters has to pass gasfilters. They consist of a high efficiency filter and an activated carbon filter, which hold back fine particles and vapours of chemical agents. Due to their cost and size, the gasfilters are installed in a limited number. This means that only a reduced amount of fresh air is passed through the gasfilter. This reduces air renewal, but is still sufficient to keep CO2 concentration, temperature and humidity in the installation within safe and acceptable limits.

- Ventilation interruption

The gasfilters have no protective effect against fire fumes and gas, such as CO and CO2. Such constructions must not be built in areas with a high risk of fire. In certain cases the ventilation may still have to be interrupted due to unfavourable conditions (e.g. to prevent an unnecessary nuisance by dust). When the number of people in the shelter allows for 2,5 m3 per person (standard value, e.g. in shelter rooms according to the Technical Directives for Private Shelters), the Coz-concentration reaches its acceptable limit of 3 percent per volume within approx. 3 hours. In case of 12 m3 per person (e.g. medical centres) it takes about 15 hours. It takes 5 respectively 25 hours to reach a CO2-concentratlon of 4,5 percent per volume, which is already a dangerous level. In order to maintain a regular air circulation within the rooms and to make full use of the available volume of air, a return air system must be installed.

- Emergency operation

Normally the ventilation unit is connected to the local electric supply system. In case of a network break down, the ventilation operation is kept up by an emergency diesel generator. This emergency power supply has to be designed in such a way to guarantee the function of the gasfilter operation in any given situation. Should the emergency power supply break down, it must be possible to keep up emerency ventilation of at least 3 m3/h per person. For this purpose the ventilation unit is equipped with a manual drive assembly.

|

Ventilation systems

On planning ventilation systems, one must take into account the following basic rules:

- ventilation components, exhaust air blowers, gasfilters and gastight shut off valves must be installed in the ventilation plant room

- the rooms are ventilated with a supply air ducting system. Exhaust air is freely released, through openings in doors towards air locks and exhaust air grills

- an exhaust air ducting system is only provided for the rooms (kitchen, toilet) connected to the exhaust air blower

- ventilation ducts must not be embedded in the ceiling

- the shelter closures have to be considered as shut for every operation type. The exhaust air is pressed outside automatically due to the overpressure inside the construction. When due to high flow resistances (e.g. grease filter of kitchen exhaust, or long ducts) the overpressure is not sufficient to force the exhaust air out, a blower can be installed.

- the ventilation systems have to be planned to be operated with return air

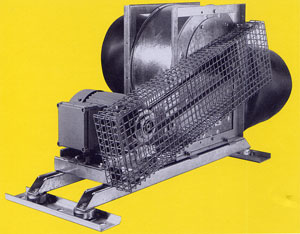

- Ventilation systems VA 40, 75, 150 and 300

These ventilating installations are applied in private and public shelters. VA 40, 75 and 150 are individual units and mainly used in private constructions.However, VA 150 can be centrally arranged in a plant room. The complete assembly consists of:

- air intake explosion protection valve with air filter

- electrically and manually driven blower

- gasfilter

VA 300 are individual units applied in public shelters for up to 800 persons. They are grouped in a plant room or arranged in groups along the shelter wall. A common air intake with explosion protection valves with air filter is installed. The unit consists of:

- electrically and manually driven blower

- gasfilter

The switching of fresh air operation to gasfilter operation is achieved by uncoupling the flexible hoses.

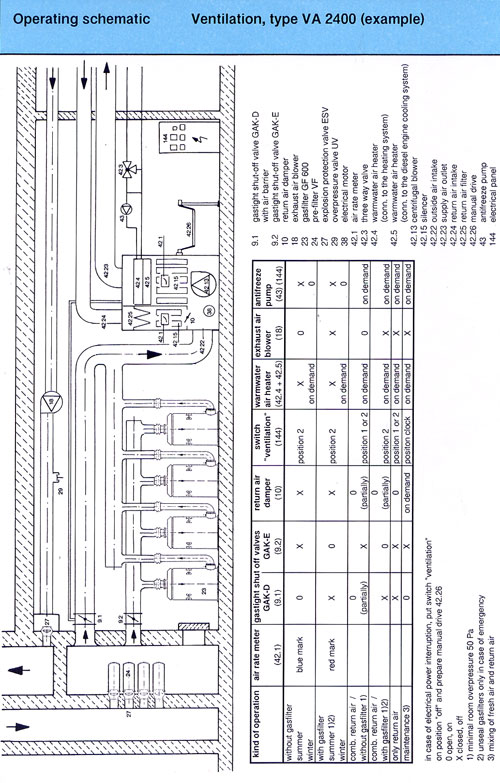

- Ventilation systems VA 1200 up to VA 9000

These ventilation units are applied in larger constructions, designed with a central ventilation plant room.

An air intake with explosion protection valves and air filter is installed. The unit consists of :

- electrically and manual driven blower

- supply air and return air sound absorber

- heating and cooling coils

- return air filter Gasfilters are arranged in groups and connected together by means of a ducting system.

The switching of fresh air operation to gasfilter operation is achieved by gastight shut off valves.

For the larger medical service installation, a separate. post air-treatment unit and a special air outlet with filter are installed for the operating theatres.

|

Components

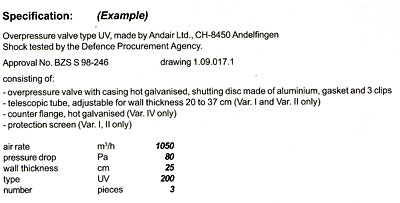

Every Andair Ltd. component such as:

- explosion protection valves

- pre-filters

- overpressure/explosion protection valves

- gastight shut off valves

- gasfilters

- ventilation units

- post air handling units for OP theatre

- air outlet for OP theatre

- shelter closures

- wall sleeves

- accessories for water tank

- ventilators

- furnishing and equipment for shelters

are designed and built to fulfill the BZS specifications and tested by the Defence Technology and Procurement Agency, NC Laboratory Spiez in Switzerland. All components have BZS qualification numbers. |

|

|

|

|

|

|

|

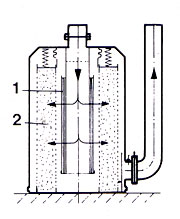

| Gas Filters |

The Andair gasfilters remove from the suctioned air all the known war gasses present under the form of gas, vapors and suspended particles (except carbon monoxide and carbon dioxide. The Andair gasfilters remove from the suctioned air all the known war gasses present under the form of gas, vapors and suspended particles (except carbon monoxide and carbon dioxide. |

Fuction: Fuction:

1. The absolute filter retains the suspended particles, in particular the chemical aerosols of war gases.

2. The activated carbon filter removes the smallest poisonous gas molecule. It consists of granulated impregnated activated carbon. |

|

|

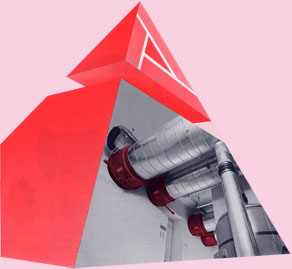

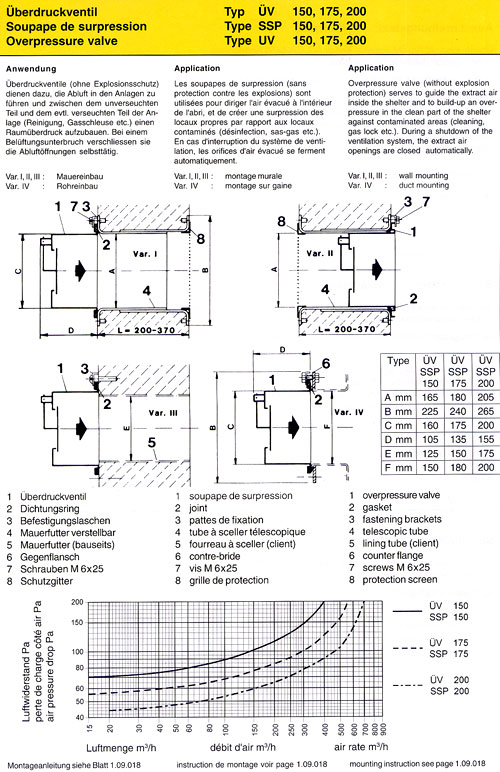

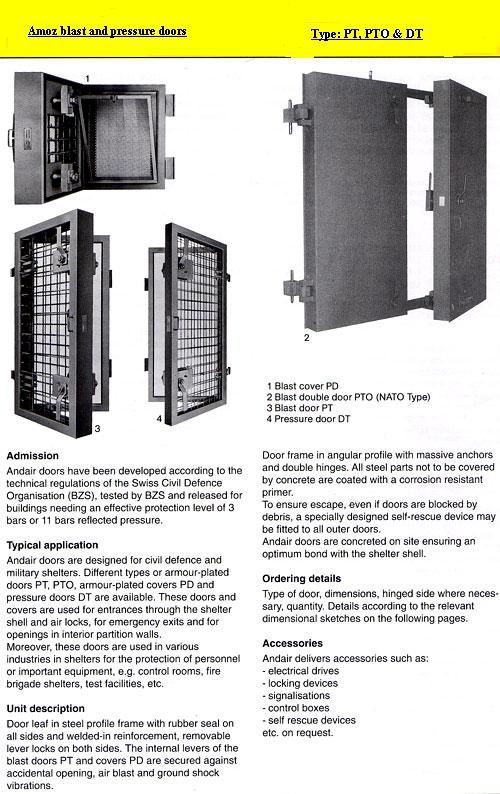

| Gas Tight Removable Disc |

They are used to shut off or change over the air flow in ducting systems. By means of these shut off devices the air is directed according to the requirements of operation with gasfilter or without gasfilter. They are used to shut off or change over the air flow in ducting systems. By means of these shut off devices the air is directed according to the requirements of operation with gasfilter or without gasfilter. |

|

|

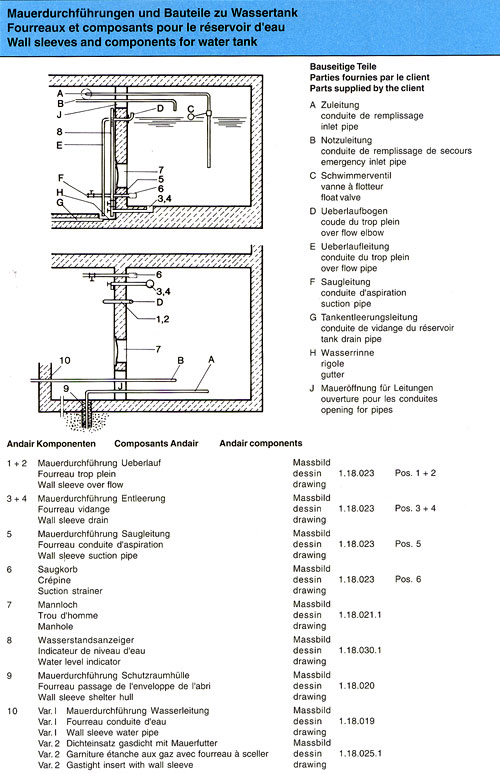

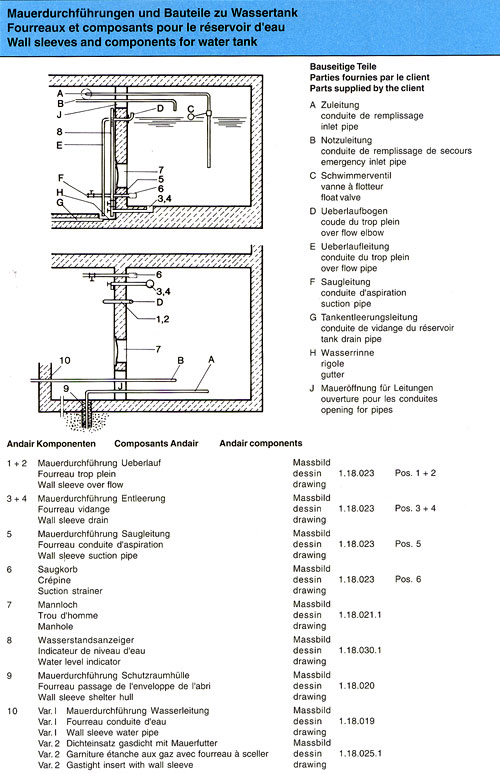

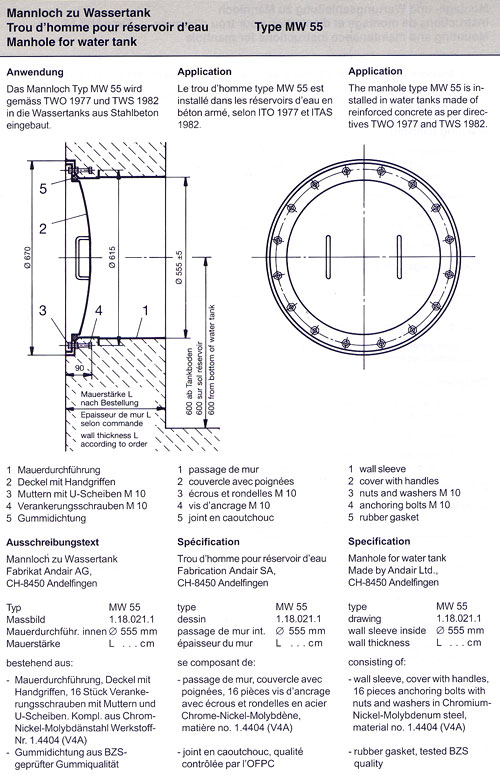

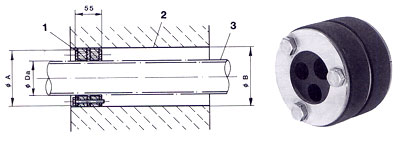

| Wall Sleeves |

Andair wall sleeves are installed in concrete walls. They permit a gastight and a pressure resistant passage of water, electricity and air. Andair wall sleeves are installed in concrete walls. They permit a gastight and a pressure resistant passage of water, electricity and air. |

|

|

|

|

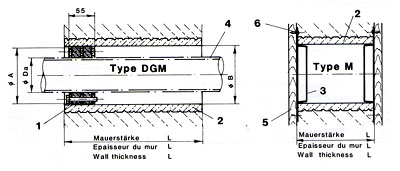

Application

The insert type DGM with wall sleeve is used for a gastight wall passage of tubes and electrical cables. These inserts are also for outside shelter wall passage with a protection degree of 1 and 3 bar.

1. insert DG

2. sleeve M

3. shuttering holder

4. tube or cable (client)

5. shuttering board (client)

6. nails (client)

Specifications

Gastight insert with wall sleeve for the wall passage of tubes and electrical cables.

Made by Andair Ltd.,

CH-8450 Andelfingen |

|

Application

The insert type DG for core drilled holes is used for a gastight wall passage of tubes and electrical cables. These inserts are also for outside shelter wall passage with a protection degree of 1 and 3 bar.

1. insert DG

2. core drill (client)

3. tube or cable (client)

Specifications

Gastight insert for core drilled holes for the wall passage of tubes and electrical cables.

Made by Andair Ltd.,

CH-8450 Andelfingen |

|

|

|

|

|

|

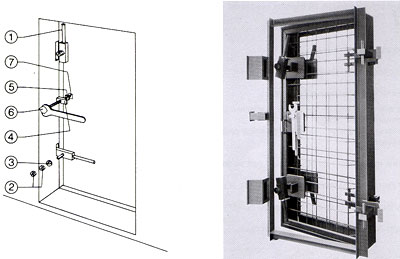

| Self Rescue Device |

|

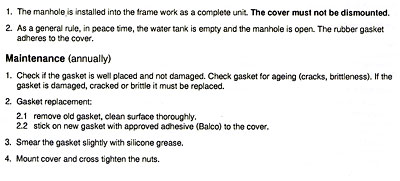

Application

In case the armoured door is blocked up from the outside by debris and the shelter cannot be left through emergency exits, the self-rescue device is used to push the door open from the inside.

The self-rescue device is suitable for amoured doors PT1, PT2, PT3.

With help of this self-rescue device is mounted on the inside of the armoured door.

Specification

Self-rescue device

Type SBV

Supplier: Andair Ltd.,

CH-8450 Andelfingen

Design according to the drectives of the Swiss Federal Office of Civil Defence consiting of: rectangular tube, spindle, special nut, spanner and mounting bracket. |

|

|

|

|

|